I’m recreating the paper form to use in a project, why you ask? I also ask myself that same question, I’m going to make a puncher and a reader, proably something ardunio driven outputting RS232 so I need to make my own cards as NOS cards are hard/expensive to find.

Links

https://www.ibm.com/ibm/history/ibm100/us/en/icons/punchcard/transform/

https://www.masswerk.at/keypunch/

https://www.jkmscott.net/data/Punched%20Cards.html

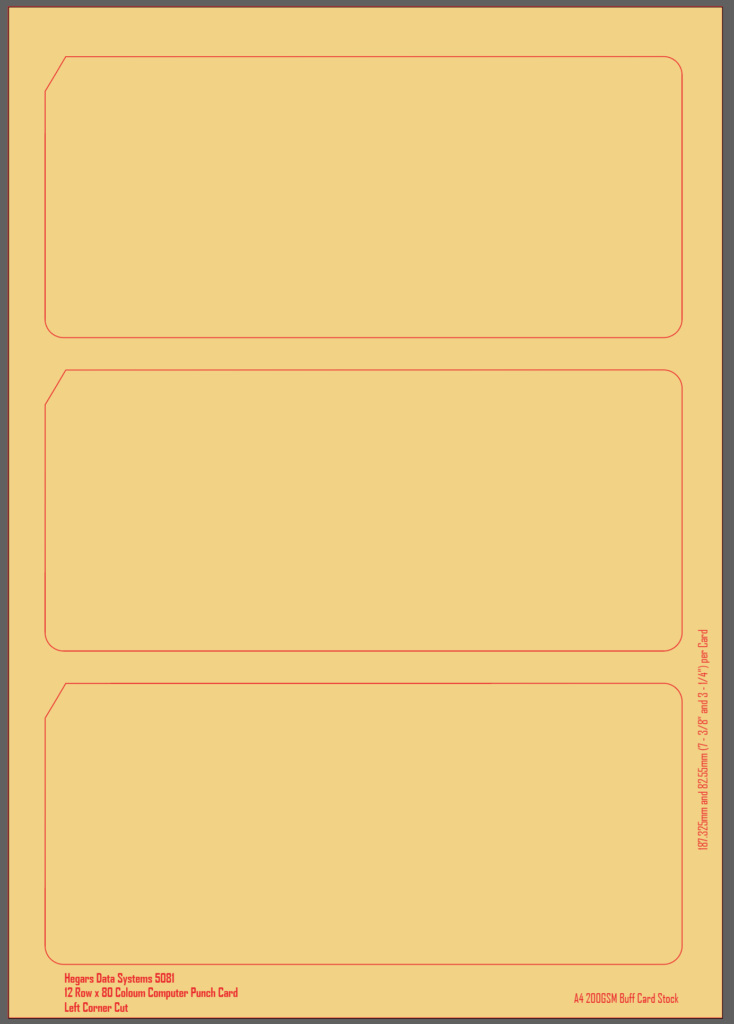

Card Dimensions

187.325mm and 82.55mm (7 – 3/8” and 3 – 1/4”) per Card

Data Density

In binary mode you have 12 Lines by 80 coloum, so in hex you get FFFF per line, 16 bits (ie; 1 word) x 80 so 80 words …..

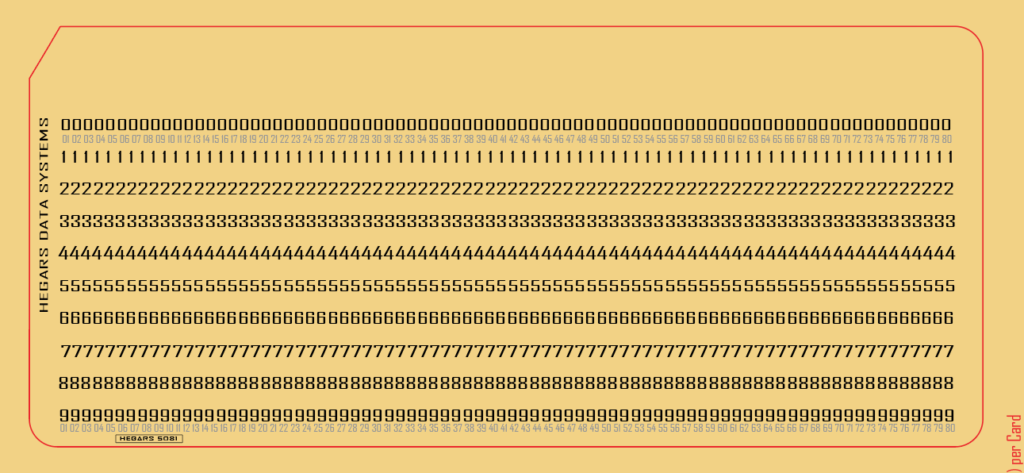

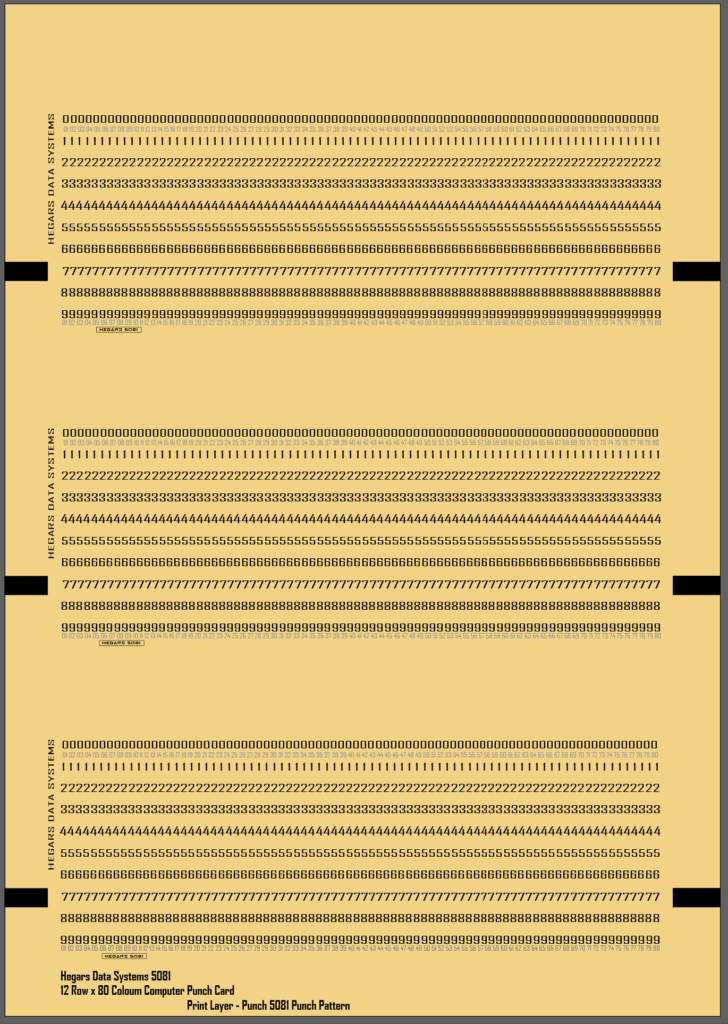

Print Design

Print overlays so i can print anything I need on normal A4 stock, using 200gsm BUFF colour paper is ~0.20mm, a real card reads at ~0.19mm

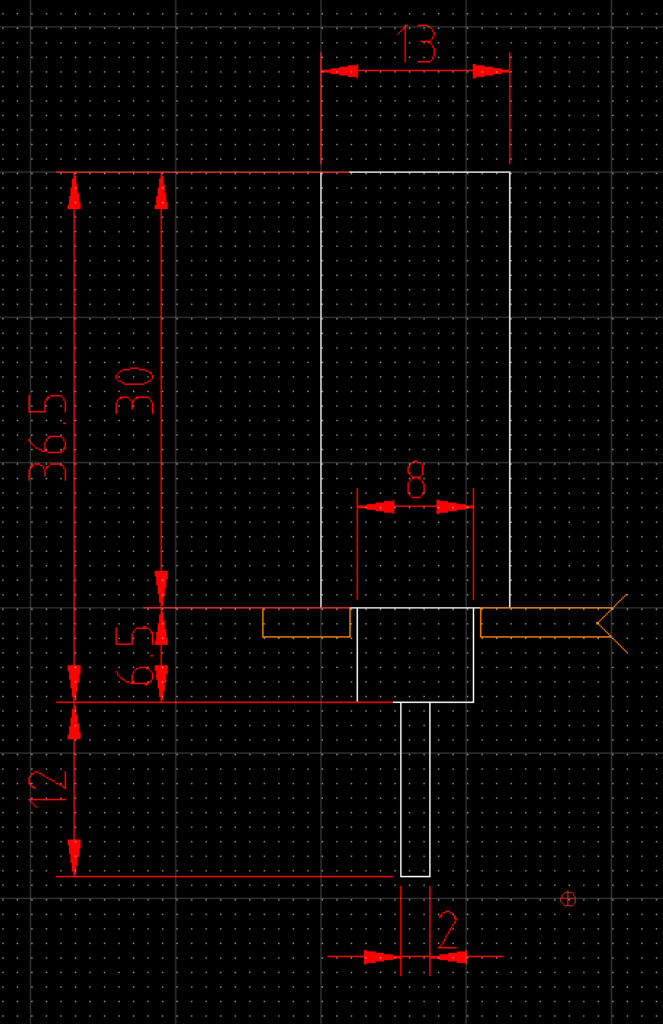

Die Frames

designs for the die lines with left corner cut, but just flip it to get right hand cut.

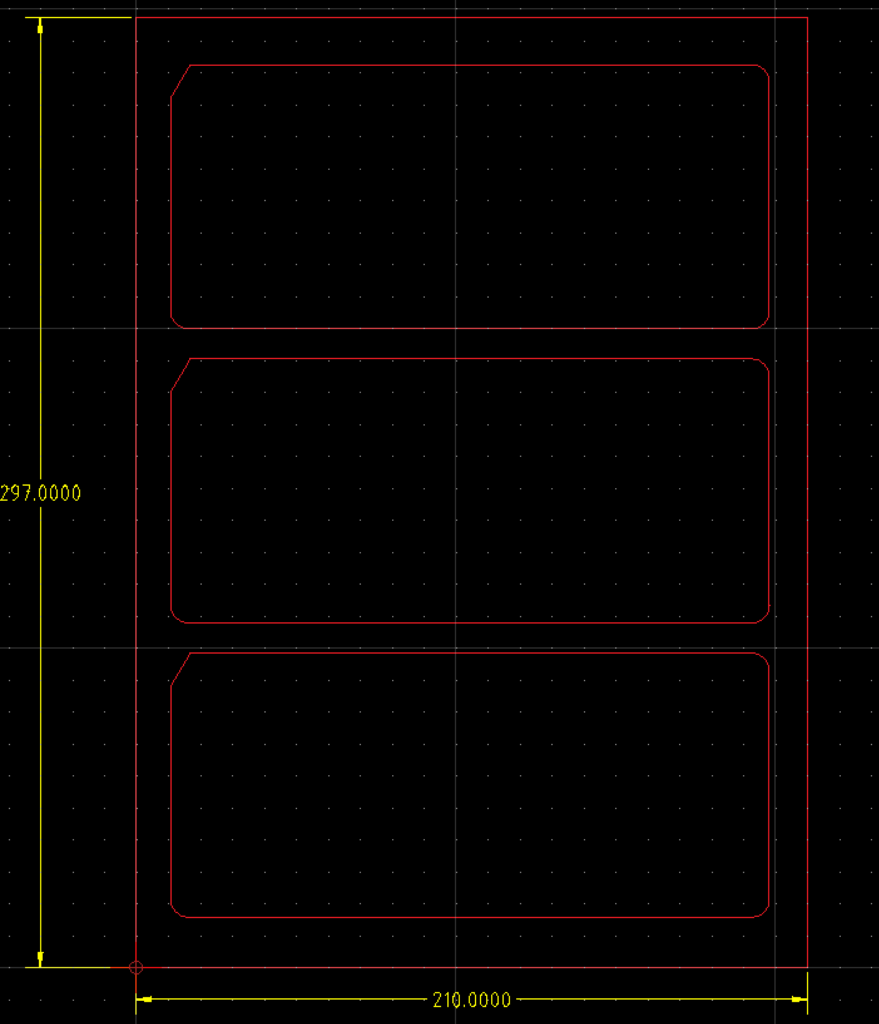

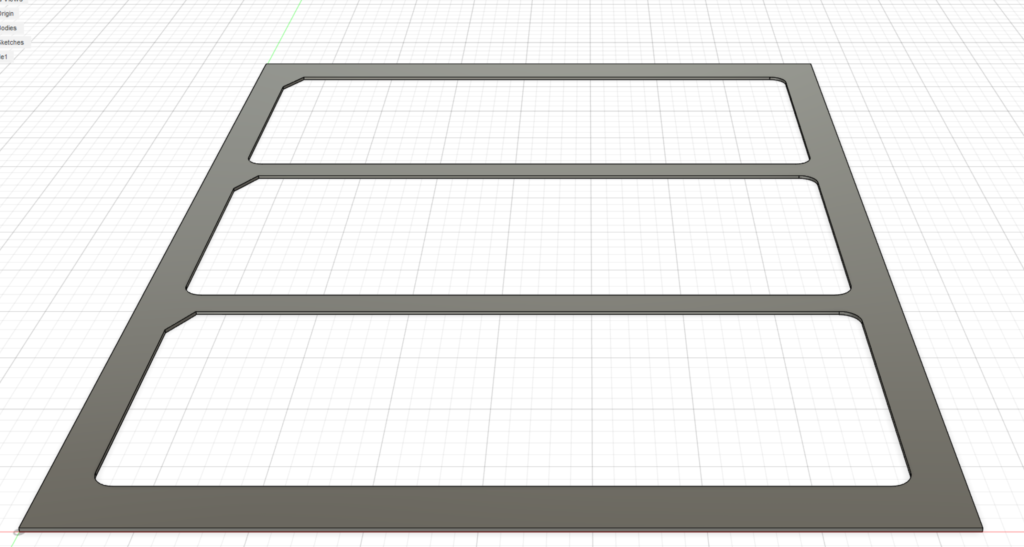

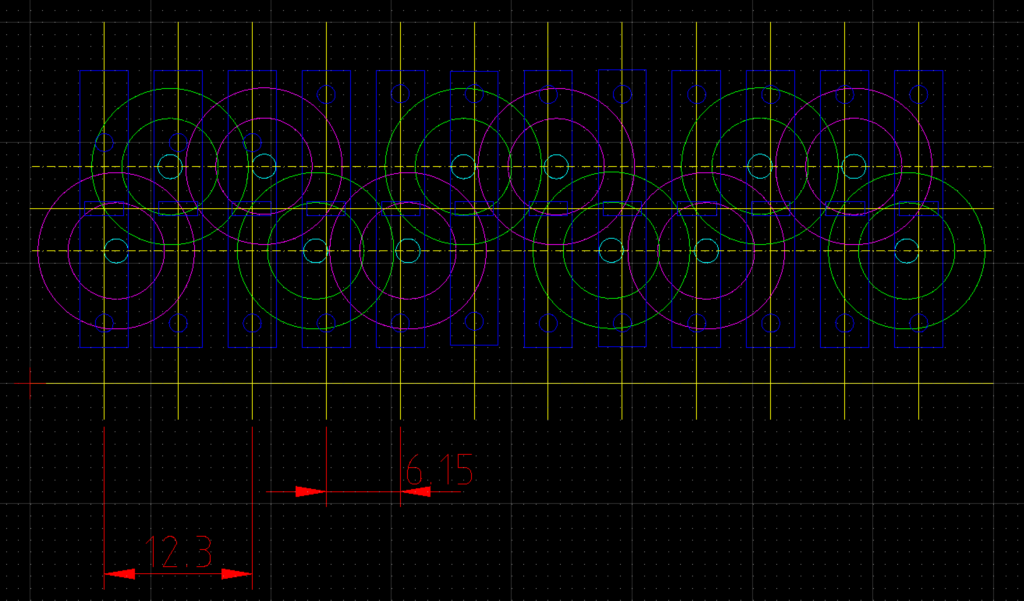

2D CAD Layout

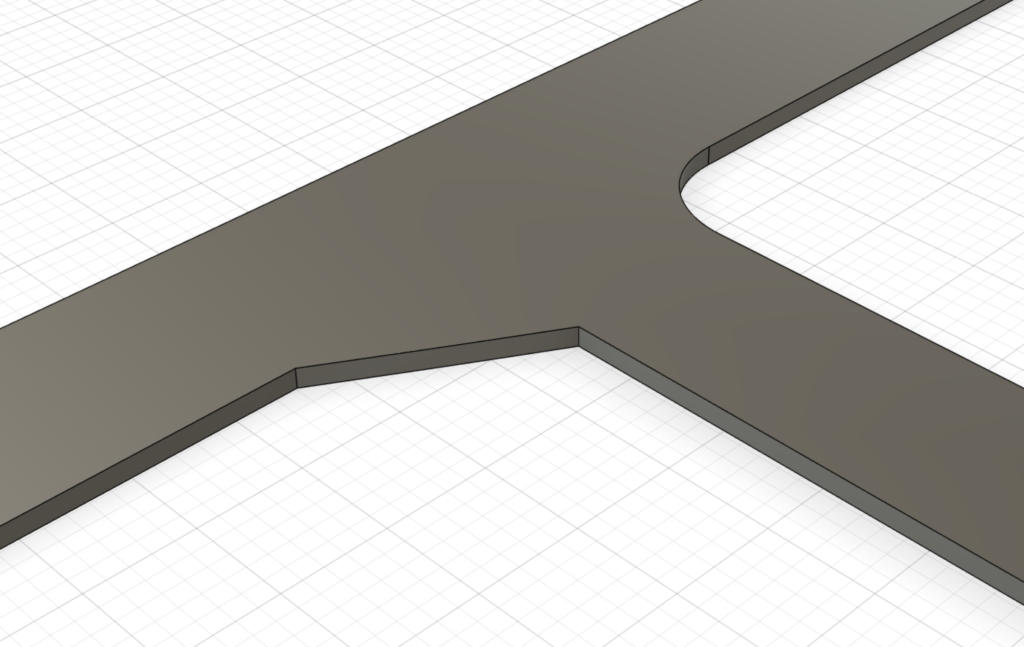

3D CAD extrusion to 1mm

Having the Tooling made in 1mm thick carbon 1018 steel amiing to use the compression method of die cutting

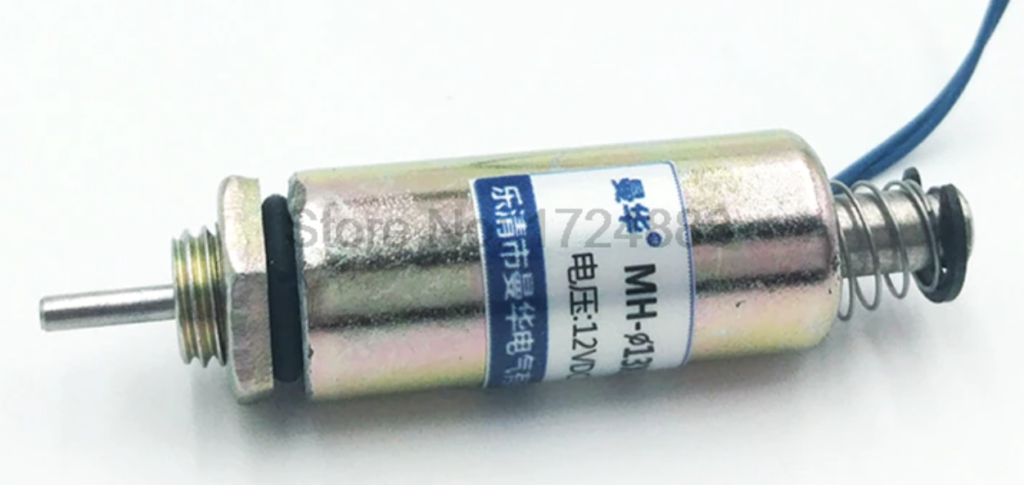

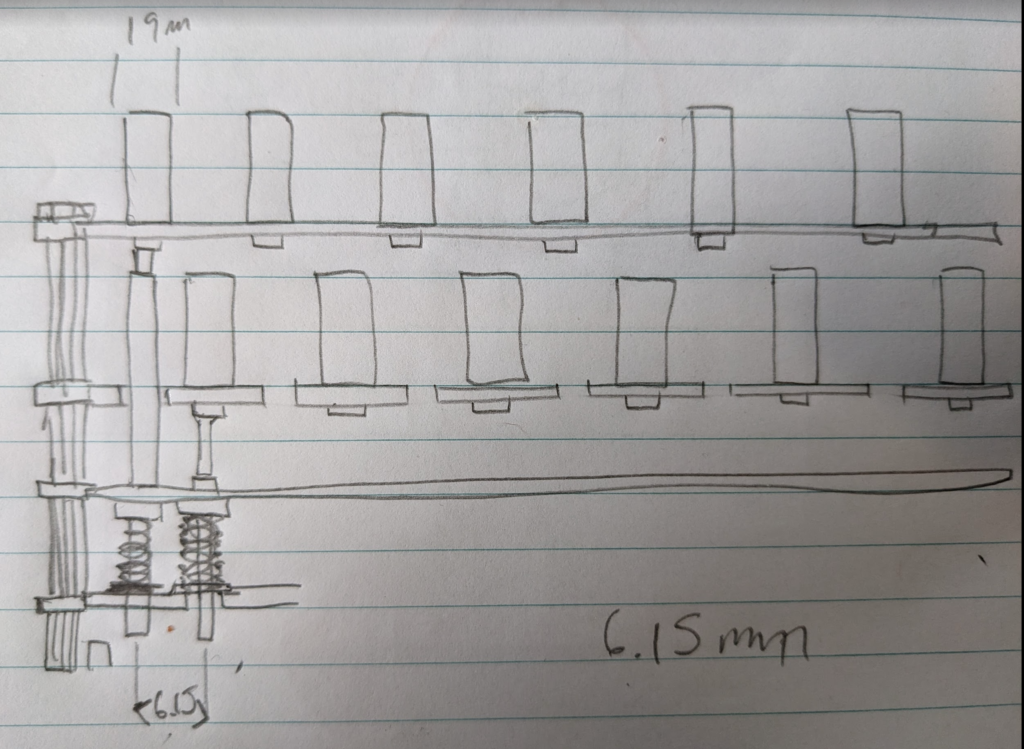

Punch Tool

punch locations are about 6.15mm apart so 12 rows

need to design some sort of frame to punch

Interleaving the solonoids for density

Reading the Cards.

Optical reads, might make passthroug read and also bounce

Electronics

flyback diodes and shit